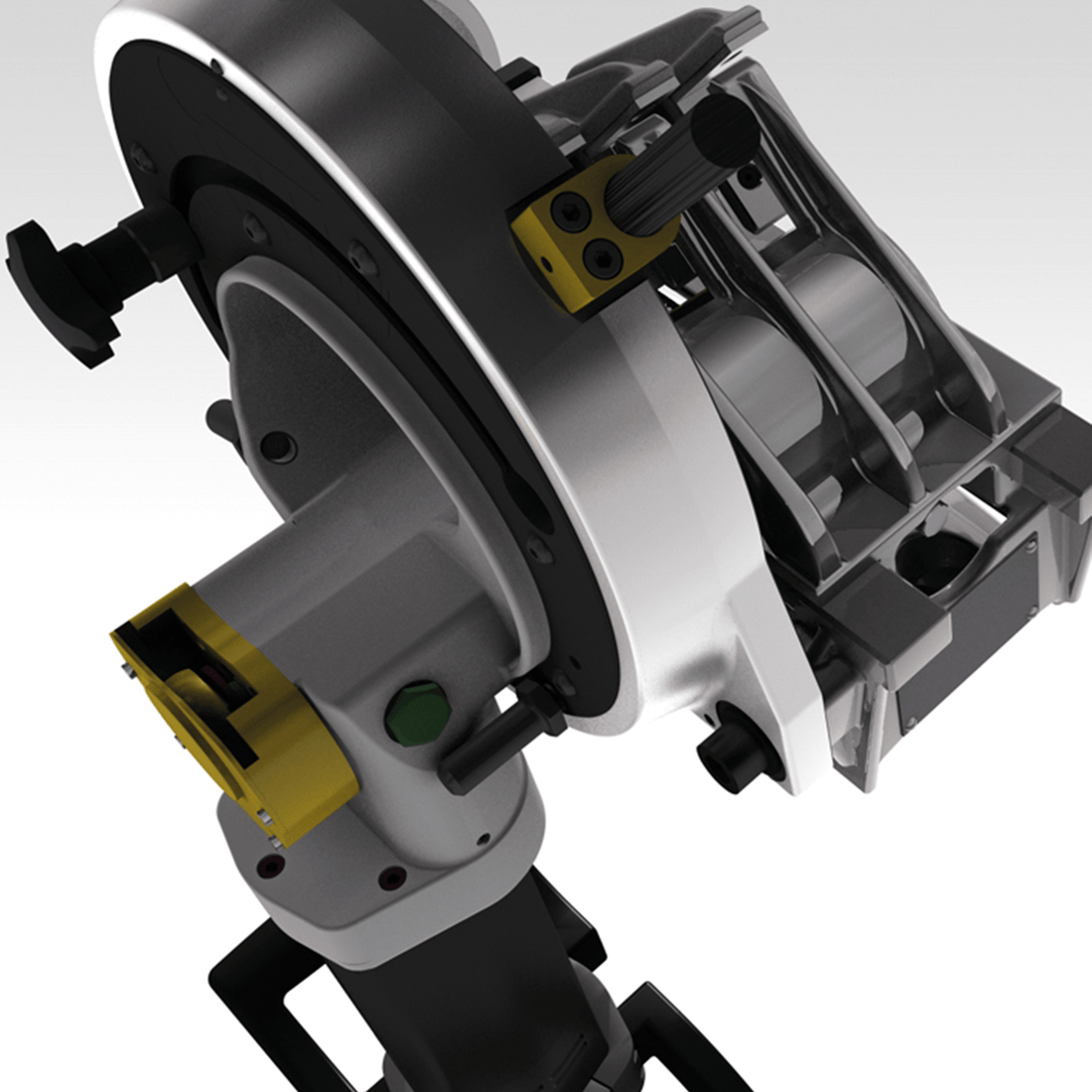

GFX 6.6 Orbital Pipe Cutting and Bevelling Saw

The GFX 6.6 Orbitalum Pipe Cutter and Beveller is an extremely low-maintenance and service-friendly pipe cutter that can process unalloyed, low-alloy and high-alloy steels, stainless steels, non-ferrous metals, aluminium alloys, titanium alloys, composite materials and plastics.

It is the ideal solution for cutting of thin-walled tubes, typical to food processing, beverage, pharmaceutical and chemical industries where it's rugged design ensures a long product life.

The GFX6.6 Pipe Cutter and Beveller conveniently uses a laser to mark the cut-off point on the tube while a second saw blade enables tube elbows to be cut off.

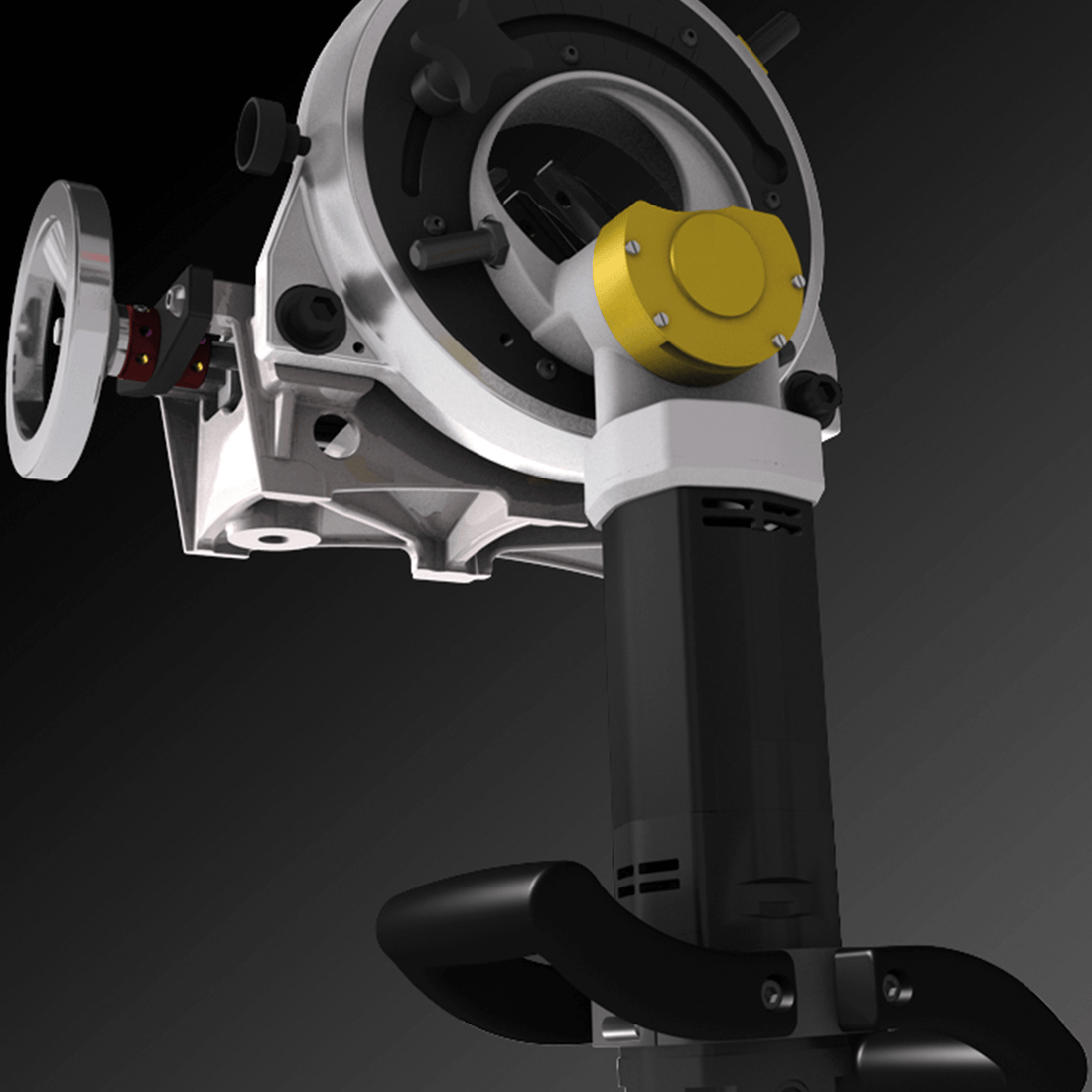

The powerful motor is equipped with overload protection and ergonomic handles and is available for the voltages 230 V, 50/60 Hz or 120 V, 50/60 Hz. See more features below.

Benefits

- Powerful Orbital Pipe Cutting machine

- 3/4" to 6" Capacity

- up to 15mm Wall Thickness cutting capacity

- Powerful 1800 watt motor

- Comes with free pipe blade, ready to go

Video

Watch a video of the GFX Series Pipe Cutters below:

Features

- Square, burr-free and cold machiningprocess

- Deformation-free clamping system especially applicable for thin-walled tubes

- Easy handling through light weight

- Simultaneous or separate cutting and beveling

- Ideal for pressfitting applications

- Second saw blade position to cut off elbows

- Optimized chip flow due to a new vice design

- Cast iron clamping jaws

- Integrated line laser to determine the cut off point

- Ergonomically designed motor handle

- Powerful drive with 1.2 kW and adjustable speed control for cutting several materials and extended tool life

- Electronic overload protection with integrated temperature monitor and electronic speed regulation

- Increased durability of tools due to the new drive GF10

- Ergonomically positioned speed control adjusting wheel

- Swivel cable with a quick-disconnect coupler: For easy and quick replacement of power cables

- Direct mounting on workbench

- Second saw blade position to cut off elbows

Specifications

Application Range

| Tube | 21.3 - 168.3 mm |

| Wall Thickness | 0.8 - 7.0 mm |

| Tube ID min. (saw blade 63/2.248") | 23.0 |

| OD range (saw blade 63/2.248") | 24.6 - 168.3 mm |

| Tube ID min. (saw blade 68/2.677") | 18 mm |

| OD range (saw blade 68/2.677") | 21.3 - 168.3 mm |

| Tube ID min. (saw blade 80/3.149") | 6.0 mm |

| OD range (saw blade 80/3.149") | 21.3 - 156.0 mm |

| Tube materials | Unalloyed, low-alloy and high-alloy steel, stainless steel, non-ferrous metal, aluminum alloy, titanium alloy, composite material and plastic |

Technical data

| Dimensions (lxwxh) | 575 x 350 x 671 mm |

| Weight incl. vice, without clamping shells | 74.4 mm |

| Power | 1200 W |

| Protection class | II |

| Built-in electronic variable cutting speed with restart inhibitor | 30 - 200 rpm |

| Versions (single-phase AC) | 230 V, 50/60 Hz EU |

| Vibration level (EN 50144) | < 2.5 m/s2 |

| Noise level at the workplace (EN 23741) | 79.7 dB(A) |

Downloads

WHAT ARE GF SAWS AND HOW DO THEY WORK?

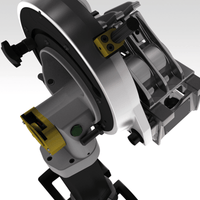

GF saws are orbital pipe cutting tools, which use the "Planetary Cutting" method of rotating around pipe to cut it rather than cutting the whole way through from one point.

By rotating around the pipe while it's held in a fixed position with a powerful clamping system, the GF saws remove the chance for a cut to fall off the square, ensuring a precise, right-angled and burr-free cut.

GF saws also have the capability to bevel a pipe, with an extra saw that can be used separately or at the same time as a normal saw, cutting pipe preparation times in half.

SQUARE, BURR-FREE CUT WITH A PERFECT BEVEL

The unique, planetary cutting method of the GF saws creates a square, burr free cut.

Add to this Orbitalum's specialised saws with bevelled teeth that can be used separately or in conjunction with the cutting saws to create a perfect bevel, and you have one machine that can do all your pipe preparation for you.

UNIQUE PLANETARY CUTTING METHOD

With the planetary cutting method, the saw blade rises into the cutting are and is driven orbitally around the tube.

This provides the advantage of a small saw blade being able to cut a large diameter tube without creating heat.

DEFORMATION FREE CLAMPING

A powerful clamping mechanism lets you cut any variety of tube easily and without the worry of deforming your pipe.

The dual position clamping jaws reduce chatter and enable smaller lengths of pipe to be machined, while stainless steel clamping attachments protect against contact corrosion.

ERGONOMIC MOTOR HANDLE

A dual sided, easy grip handle alllows for better ergonomics to provide for a safer, more comfortable operating position.

REDUCED OPERATOR FATIGUE

As well as a manual cutting mode, Orbitalum GF Cutters offer an automated cutting process feed module, that allows operators to set the machine up and leave it to complete the cut on its own.

LASER PRECISION CUTTING

An integrated laser-precision line makes sure you always cut exactly where you intend to.