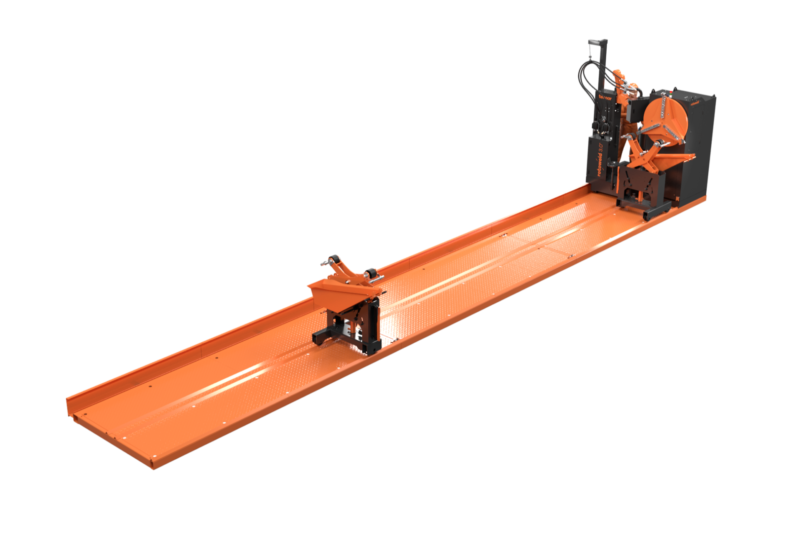

Rotoweld 3.0 Single Bay / HD

$0.00

Ex GST

If you think you will encounter bigger jobs in weight, diameter or overall spool size, the Rotoweld Single Bay 3.0 / HD has that little extra you might need.

Engineering on-demand for an important client, this version of the Rotoweld is now offered to all who want to push the highest level of automation to a broader range of spools.

- 3" to 48" Diameter Capacity

- 15,000lbs Pipe Stand Capacity

- 150+ dia inch Daily Productivity Capacity